Sleeves Manufacturing

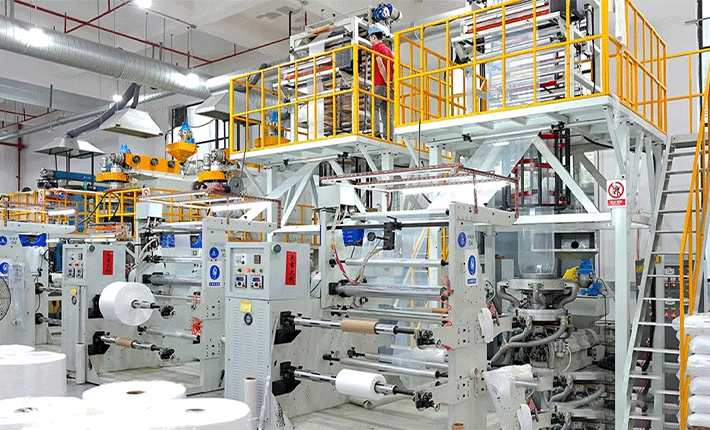

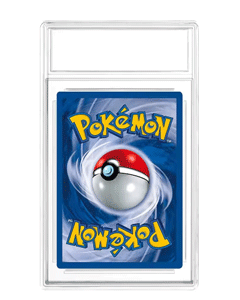

Precision and Quality: Our sleeve manufacturing process ensures the highest standards of precision and quality. This involves meticulous selection of materials and advanced production techniques to create durable and visually appealing card sleeves.

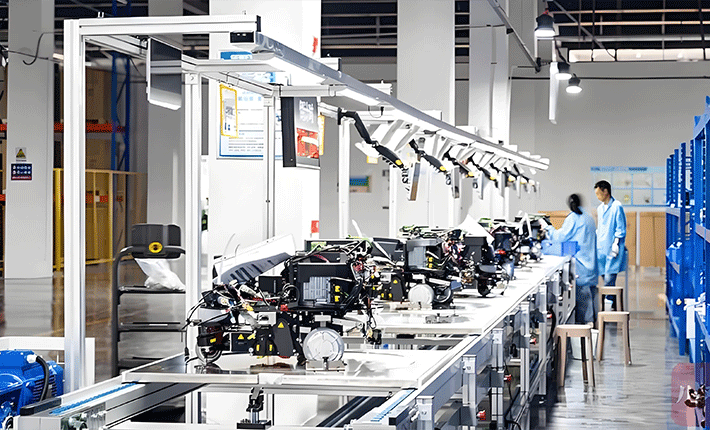

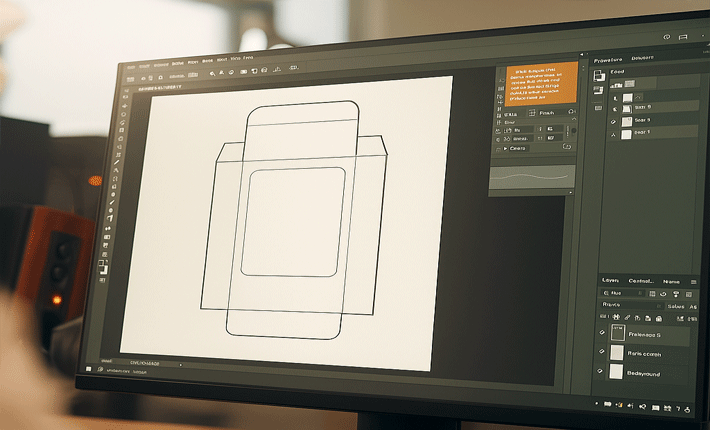

Custom Design Integration: You can collaborate with Guard TCG's designers to build a unique sleeve design that meets your requirements, or you can supply artwork or graphic files that incorporate your branding. We specialize in bringing your custom vision to life on our sleeves.

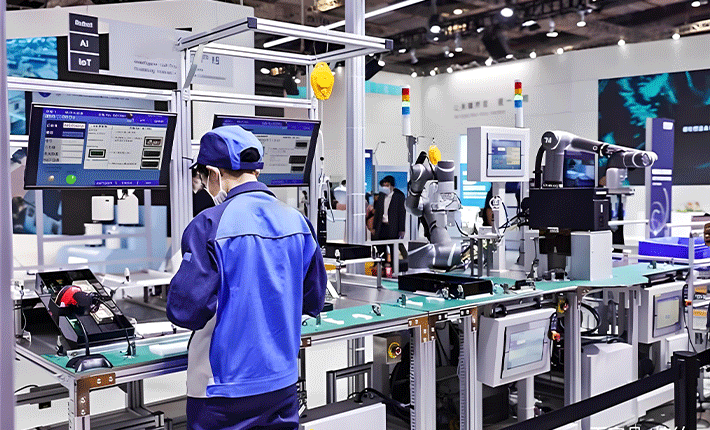

Advanced Printing & Finishing: The card sleeves will undergo advanced printing and finishing processes during manufacturing. This ensures that your custom designs, logos, and any other identifying information are perfectly integrated and ready to be shipped to you or your clients as a completely branded product.